The development of electric vehicles is gathering speed. China has set itself and car manufacturers ambitious targets, and aims for 12 per cent of all vehicles to be electric by 2020. France wants all cars sold after 2040 to be electric. Volvo has announced its intention to end the production of vehicles powered by internal combustion engine in 2019. The London Taxi Company has also signalled its intention to enter the electric vehicle market by changing its name to the London Electric Vehicle Company. The new taxis will have the same classic look as their predecessors, but will be cleaner and quieter. The UK government has recognised the shift towards electric vehicles, and in July 2017 announced a major investment programme to develop battery technology.

The pilot project Automated Module-to-pack Pilot Line for Industrial Innovation, or AMPLiFII for short, is demonstrating how efficient automation can contribute to the competitive production of traction batteries in Europe.

Developed for small spaces

Within the AMPLiFII pilot battery assembly line, special purpose machine builder and system integrator Horizon Instruments has developed a high-speed cell picker system. This presented a unique challenge for Technical Director Daniel Bolton and his team. When designing the battery module production line they faced several technical and practical constraints: “We had a relatively confined space in which to fit the equipment and strict budget parameters, as well as a lead-in time of just seven months. We also needed to find a way of electrically testing each cell, rotating cells when needed and placing them into each module extremely precisely and at great speed.” One of the core tasks of the pilot plant is the simultaneous testing of groups of 30 cells for current and voltage before they are picked and placed in the battery modules. The high costs and space constraints meant that it was not possible to accommodate 30 individual battery testers. A solution had to be found. Together with the research and education group WMG at the University of Warwick, Horizon Instruments developed a bespoke multiplexer interface which allowed a single battery tester to be used. This not only delivered savings on space and capital cost, but also enabled the collation of comparative data regarding test status.

A custom solution in eight weeks

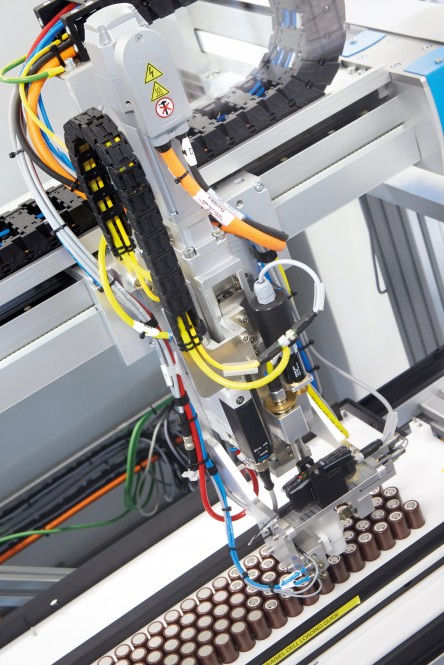

After testing, the battery cells are aligned accurately and inverted if necessary. The pick and place system then inserts them into the module located on a conveyor. The plant can be configured to handle the exact number of battery cells, which can sometimes vary. 100 individual cells per module is typical, with a total weight of approximately 9 kg once assembled. Festo delivered a compact complete solution using Cartesian robot technology for fast and precise handling. “We didn’t need to coordinate multiple suppliers or worry about product compatibility”, explains Daniel Bolton. “Within just eight weeks of the order being placed we had a custom system. Festo also provided us with technical support throughout the design, installation and commissioning process.” With the new automation solution, each cell can be picked, rotated, aligned and placed in the modules within 1.2 seconds.

UK premiere

At the heart of the battery pick and place system is the Festo EXCH-60. The planar surface gantry is aimed at high-speed assembly operations where small, light mass-produced items need to be positioned quickly and flexibly. Powered by two fixed motors, the EXCH delivers an optimum dynamic response. By eliminating the need to use separate gantries for each axis, it delivers precise alignment. At speeds of up to 5 m/s and acceleration rates of up to 50 m/s2 it is capable of 100 picks per minute with a repetition accuracy of ±0.1 mm. For Steve Sands of Festo, using the EXCH is a significant step: “This project is the very first time that the planar surface gantry from Festo has been used in the UK. The automation technology now incorporated in this pilot line for electric vehicle batteries was originally developed for the construction of solar panels. It is ideal for handling delicate components and placing them with great precision.” The 2D planar surface gantry is controlled by a CPX valve terminal. It allows state-of-the-art electronics and pneumatics to sit on a single, stand-alone base.

Paving the way for the future

The new automation solution has generated interest beyond the machine building and automation technology sectors. For Professor Robert Harrison of the University of Warwick, the pilot project is proof “that the high-speed cell picker and other stations will allow us to demonstrate our ability to automate the cell-to-module packaging process and help pave the way to upscale to a full production plant.” Professor Harrison believes that the project will help develop the next generation of traction batteries for electric and hybrid vehicles. “It will combine the best human and automated assembly methods to manufacture battery packs and lay the foundations of a new UK automotive supply chain based around automated technology”, says the automation systems expert.

WMG

Coventry CV4 7AL

University of Warwick

United Kingdom

Area of business: Research and development

Horizon Instruments

Ghyll Industrial Estate

Heathfield, East Sussex

United Kingdom

Area of business: Design and build integrated automation solutions