End-to-end competency from Festo

Find out more about our solutions for your specific area of automotive production. Simply click on the relevant area of production to view the matching products.

Precision handling in the press shop

The bottom line here is that the systems have to operate accurately at the highest possible speed while exerting enormous forces. As a result, functional safety is extremely important. For the press shop, we primarily offer solutions for high-precision handling and gripping tasks, such as feeding in and separating sheet metal, securely fixing, lifting and transport, which have proven to be sturdy, durable and economical.

Like our vacuum generators OVEM and OVEL. These vacuum generators combine vacuum generation and monitoring in one compact unit. OVEM, with its integrated air saving function, has industrial energy efficiency built in. A check valve prevents compressed air from being used unnecessarily for holding. Both vacuum generators are effectively maintenance-free.

Another advantage is that

the built-in IO-Link® technology makes the vacuum generators Industry 4.0-capable.

High-precision welding and handling in the body shop

Car body construction in automotive manufacturing is a job for welding robots. Here, sturdy solutions have to position the sheet metal with great accuracy and repeatability, supply the line with small parts and the welding guns with compressed air and cooling water. With a special focus on car body construction, Festo has developed Industry 4.0-capable components for servo-pneumatic welding guns. We offer complete, application-specific solutions to guarantee a reliable supply of compressed air and cooling water for individual welding robots or entire welding lines. The design is pretested, tailored precisely to your body shop specifications and ensures that you have a structured and bundled media supply. As a result, the welding points remain reliably reproducible.

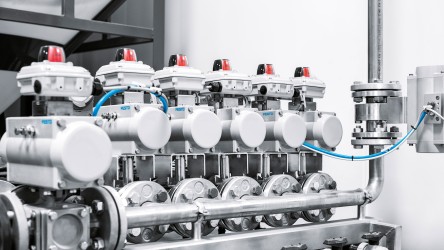

And our flagship, the valve terminal VTSA with the terminal CPX, is also on board. It combines I/O modules, valve functionality and safety functions to ISO 13849-1 into one unit, including the exhausting of system components, reversing and protection against restarting. The high degree of function integration and the flexible connection to all common fieldbus systems transform this automation solution into the decentralised intelligence in Industry 4.0 scenarios.

Industry 4.0 command centre

Automate your production with the decentralised CPX/VTSA solution. It combines valves, I/O modules and safety functions with extensive fieldbus and IO-Link® options.

Error-free, high-speed painting systems

A precise compressed air supply with the required air quality plays a key role in ensuring that the car bodies pass through the paint shop at high cycle rates and with consistent quality. Festo provides a range of solutions and components for this.

With our service unit components from the MS product series for compressed air preparation, you can combine different sizes, filter cascades and air dryers for the required, energy-optimised compressed air quality.

The compact proportional flow control valves VPCF from Festo are designed to deliver accurate spray jet control in critical environments such as painting systems. It is IP65-classified, has ATEX approvals and is free of PWIS, of course.. The high dynamic response enables variable cycle times: never more than is needed and avoiding any time loss.

Record-breaking speed in powertrain production

Festo offers components and systems for the rapid and precise movement of loads, ensuring both fast transport and the implementation of extremely precise monitoring tasks.

The range of electric or pneumatic stoppers brings loads of up to 800 kg to a stop reliably, gently and without any vibration. It is designed for the typical conveyor belt speeds found in powertrain production.

And our flagship, the valve terminal VTSA with the terminal CPX, is also on board. It combines I/O modules, valve functionality and safety functions to ISO 13849-1 into one unit, including the exhausting of system components, reversing and protection against restarting. The high degree of function integration and the flexible connection to all common fieldbus systems transform this automation solution into the decentralised intelligence in Industry 4.0 scenarios.

Reliable final assembly

We deliver suitable solutions for fully automated motion sequences and for safe, flexible human-machine interaction. This includes components for reliable positioning and an extensive product portfolio for handling and assembly as well as various grippers and vacuum systems.

As part of the human-machine interaction, our servo-pneumatic balancer system YHBP moves loads around during assembly as if they were weightless. It also adheres to the safety standard Performance Level d for loads up to 999 kg. And if the power fails, the load will be prevented from falling.

We also have a world first for you: the clip fix tool AGTC. It takes care of laborious, ergonomically stressful tasks with a perfectly reproducible compressed air pulse that automatically fixes the assembly clips in position. This creates a more reliable process and relieves the strain on your colleagues in production.

Who else should know about this?

You’ve already got enough to deal with, but co-workers are usually grateful for some tips. You can use this link to easily share the information on this page.