Battery production process

For each of the numerous steps involved in producing batteries, Festo offers the right automation solutions, whether pneumatic, electric or a combination of several technologies.

Reliable raw material feeding

In battery cell production, the liquid and granular raw materialsare fed in using pneumatically controlled process valves. These materials are often extremely abrasive and corrosive. To make surethe process is reliable, the automation components required need to be extremely sturdy.

This is precisely what the high quality butterfly valve units from Festo, made up of a butterfly valve, rotary actuator, pilot valve andsensor box, offer. They are also fully pre-assembled and tested, making commissioning fast and efficient. Pneumatic actuation takes place using the new modular control system CPX-E together with the attractively priced valve terminal VTUG from the Festo coreproduct range, as well as the tubing PUN-H, fittings QS, one-way flow control valve GRLA.

Accurate mixing

During mixing, a homogeneous coating paste (slurry) is produced that is applied to the electrode foils during the subsequent coating process.

To feed the raw materials into the mixer, Festo offers a complete unit made up of ball valve, quarter turn actuator, pilot valve and sensor box. The assembled and tested unit ensures that the active materials, conductive additives, solvents and binders are fed through in the precise quantity required by the recipe and conveys them at the correct flow rate. If a proportional controller is required, then the positioner CMSX can also be used.

Properly controlled drying

To dry the electrodes, the process chambers are continuously evacuated to remove moisture. To do this, a vacuum needs to be created in the dryer, controlled by the process valve units described in previous process steps. The moisture-laden air is evacuated from the unit using a butterfly valve or a ball valve. Festo offers both types. The mounting method is determined by the customer. The positioner CMSX is ideal if a proportional controller is required.

Highly precise calendering

After drying, the electrode foil is cooled, compressed by rotating rollers and homogenised. As part of this process, the foil is fed over different guide pulleys and precisely tensioned and relaxed using a dancer controller. For an even feed speed, the foil must also be temporarily stored in dancer rollers.

This can be done using the standards-based cylinder DSBC in combination with a pressure regulator VPPE or the new VPPI. The DSBC is also available in a low-friction version. If only short strokes are required, the unique fluidic muscle DMSP is recommended as an actuator. The DMSP is also friction-free, which means it works with absolute precision and achieves maximum repetition accuracy. Pneumatic actuation takes place using the attractively priced valve terminal VTUG together with the individual valve VUVG from the Festo coreproduct range, as well as the MS service units, tubing PUN-H, push-in fittings NPQR.

Cutter-protective slitting and secure fixing using web catchers

The purpose of slitting is to cut a wide strip of electrode foil into several narrower strips. This cutting process can be done thermally using laser cutting or carried out mechanically using a rolling cutter. To extend the cutter’s service life, a cooling liquid is sprayed directly onto the blade during this process. The liquid must be dispensed in a controlled way and in very small quantities. The dispense head VTOE from Festo is perfect for this task.

If the machine stops during the slitting process, the electron strips are secured using so-called web catchers. Fast-switching valves MHE4 and cylinders DSBC with low friction properties are used to ensure a fast response time and speed.

Perfect dust removal during slitting

The dust particles produced during slitting are collected by a special vacuum-based dust extraction system. This vacuum is regulated by process valve units with ball valve (consisting of SRBC, DPFD, VSNC, VZBD) or with a butterfly valve unit.

The dust deposits are removed from the dust collection containers using pulse valves. The pulse valve VZWE with its high flow rate is ideal for this task. The entire system can be controlled using a CPX-E. All valves VZWE that are used can be actuated in series as a group with a single signal via CPX-AP-I modules; this makes installation much easier.

Fast tool changes during punching and separating

In the next stage of the production process, the electrical contact tabs are punched out of the electrode strips. When producing pouch cells, the electrode strip is also cut into separator sheets. This process requires machines with very heavy cutting or punching units. They are often so heavy that activities such as tool changes cannot be carried out manually.

With the balancer solution YHBP from Festo, even heavy tools can be moved and changed quickly and safely when servicing is required. The bellows cylinder EB is the perfect solution for loosening the tool from its position since it requires very little height. This means it fits easily under the tool yet still has enough force to lift the heavy part. The EB together with the balancer kit YHBP is therefore the perfect combination for changing heavy tools.

Precise and energy-optimised punching and separating

Depending on the plant concept, the separated sheets are stored in a magazine after the punching process or transferred directly to the next process step. For safe transport, the sheets are secured on the perforated transport belts using vacuum.

The vacuum required for this is regulated using a process valve unit, consisting of a butterfly valve KVZA, a rotary actuator DFPD, a pilot valve VSNC and a sensor box SRBC. A manually actuated ball valve VZBF acts as a drain valve. The individual vacuum lines are regulated by a pinch valve VZQA, which is actuated using a proportional pressure regulator VEAB. This facilitates precise regulation of the required vacuum level, and also optimises the energy consumption.

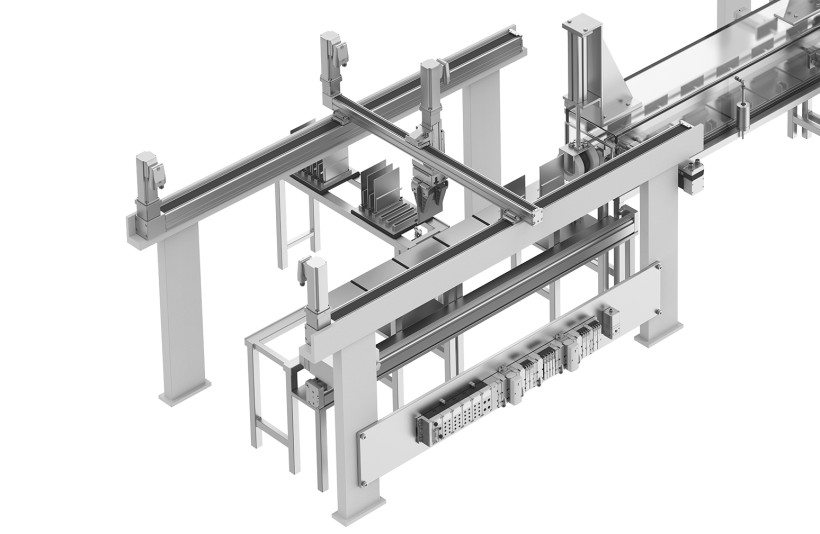

High-speed stacking

In the production of pouch cells a stacking process is used; producing round cells and prismatic cells also requires a winding process. In the stacking process, the electrode sheets are stacked in a repeating cycle of anode, separator, cathode, separator, etc. Festo offers complete electric handling systems for this particular process step, consisting of axis kinematics, motors and servo drives. All the components are perfectly matched. The ready-to install gantry solutions EXCM, EXCH, YXCR are designed using combinations of the cost-efficient electric axes ELGC, mini slides EGSC and rotary modules ERMO.

The very high speeds required for maximum output are provided by the fast-switching valve MHJ9 with switching frequencies of up to 500 Hz. The vacuum needed to pick up and transfer the electrode sheets is generated using vacuum generators VN. The upwards and downwards movements of the magazines are carried out cost effectively by the electric cylinder EPCC or electric linear axes EGC. The processes can be monitored by a wide range of sensors or cameras offered by Festo. Last but not least, everything is controlled using the new control system CPX-E.

Precision for perfect winding

There is a brief stop before the electrode strips are wound so that they can be cut to the required length by a stationary cutting tool. Then the cut daughter coils are fed quickly and precisely into the winding machine. This calls for a high-precision loading system with synchronised movements. The necessary precision is provided by a handling system consisting of grippers DHPS, pneumatic valves VUVG, electric spindle axes ELGC-BS, servo motors EMMT-AS and servo drives CMMT-AS. It too is controlled using the new, modular control system CPX-E.

Round and prismatic battery cell: precise and clean winding and cutting

The winding process for round cells and prismatic battery cells involves producing a “jelly roll” consisting of an anode strip, a separator and a cathode strip. To accurately control the motion of the strips, a large number of dancer rollers and web edges must be moved precisely and smoothly. To achieve this, the fluidic muscle DMSP, the proportional pressure regulator VEAB and the precision pressure regulator LRP are combined into an innovative solution.

The DMSP is a completely frictionless actuator, while the VEAB’s unique piezo technology means its control behaviour is totally consistent. Together they result in an extremely precise dancer control system. As soon as the jelly roll of a prismatic battery cell has reached the required thickness in the winding process, the electrode strips lying on top of each other are cut through. In this application, the cutting process needs to be carried out extremely precisely and reliably and also in a very limited space. The clean design compact cylinder CDC is the perfect solution here. Its smooth surfaces and the integrated proximity sensors mean that the CDC is very easy to clean and electrode particles produced during cutting, for example, can be easily removed.

Safe and precise filling with electrolyte

Once the cell stack or jelly roll has been inserted in the battery housing, the battery cell can be filled with electrolyte. The electrolyte is dosed using the diaphragm valve VZQA. The diaphragm valve is actuated by individual valves VUVG or valve terminals VTUG – all compact, high-performance and attractively priced valves from the Festo core product range.

The extreme ambient conditions during the filling process call for materials that are resistant to chemicals and high temperatures. Pneumatic tubing PFAN and the stainless steel fittings NPQR are perfect for this task. Since electrolyte reacts with water and forms hydrofluoric acid, the ambient air must be very dry when filling the battery cells. To ensure this is the case, the air is continuously evacuated and removed from the machine cell. The vacuum required to do this is generated centrally via a vacuum pump. The regulating function is carried out by a system of diaphragm valves VZQA, pilot valve terminals VTUG and pressure sensors SPAN.

Accurate and reliable positioning for formation

Formation refers to the initial process of charging/discharging the battery cell. The cells are stored in formation trays in rack systems and are repeatedly charged and discharged during formation. This process takes a few hours. Since the formation shelves are very large, handling systems with long axes and high speeds are required.

Here, Festo can rely on many years of experience with comparable systems for testing hard drives. The range therefore also includes numerous solutions for loading and unloading the formation trays such as handling systems with electric gantry axes ELGA and electric slides EGSL as linear positioners. The major advantage of the ELGA is the magnetically sealing stainless steel cover strip, which reduces particle emissions to a minimum. The axes are driven and controlled by the servo motors EMMT-AS and the servo drive CMMT-AS. The motion function is executed by the new modular control system CPX-E with CODESYS programming. The Festo camera system SBOI ensures that the battery cell is precisely positioned on the charging position.

Precisely controlled degassing

During the formation process, gas builds up in the battery cell. This must be siphoned off from the already sealed battery cells – without losing electrolyte. This is done by piercing the battery cell using a hollow lance and evacuating the gas until electrolyte is being drawn off too. The system then switches over and blows the drawn off electrolyte back into the battery cell, while the remaining amount of gas is permanently removed.

The vacuum required for this is also generated via a vacuum pump and controlled by pinch valves VZQA and pressure sensors SPAN. Since the vacuum and the blowing pulse need to be carefully controlled during this process, the proportional pressure regulator VEAB in combination with highly precise pressure sensors SPAN is also recommended.

Different handling solutions for module assembly

Once the individual battery cells have been produced, they are combined into battery modules. This is done by installing a specific number of round or pouch cells in module housings and securing them in place using bonding processes. The required amount of adhesive components or adhesive can be precisely dosed using a poppet valve VZXA or a complete process valve unit with ball valve, quarter turn actuator, pilot valve and sensor box.

The dispense head for placing the glue points or applying a glue bead is moved using handling solutions from Festo. The battery cells are inserted into the battery modules using pick & place applications. Depending on the length of the axes and the demands for accuracy, gantry systems with individual axes EGC or highly dynamic planar surface gantries EXCH are suitable for this task. All axis systems always feature the servo motors EMMT-AS and the servo drives CMMT-AS.

Prismatic battery cell: cost-effective pressing

Before the wound electrode strips are inserted into the battery housing, they must be compressed during a pressing process. The servo press kit YJKP is ideal for a pressing application of this kind.

It includes three components: a modular controller, operating software and the matching electromechanical system from Festo. This results in a package including spindle-driven press cylinder, motor, motor controller, force sensor and controller – everything you need for electric pressing applications up to 50 kN. Loading and unloading is done using a pick & place solution with electric axes, such as the electric axes ELGC and EGSC that are connected together and combined with a vacuum gripper solution.

Boost productivity for Battery Production

In the key steps of lithium battery cell production, like "formation" and "degassing", involves frequent charging and discharging in order to activate the cell will produce a large amount of gas, which needs to be removed from the packaged battery through the process chamber. Festo products not only meet the requirements of high-speed, high throughput, repetitive and accurate production, but also ensure the safe production of the cell from the raw material side.

Speed and precision for your battery manufacturing

From cells and module production to inserting the battery systems, Festo has the right automation solutions for the entire battery manufacturing process, be it pneumatic, electric or hybrid. In battery manufacturing, high throughput and repeat accuracy are just as important as cost-effective solutions. This applies to many different process steps, from conveying, supplying and controlling aggressive media to precise parts handling and force-controlled pressing applications.

Festo product portfolio for battery production

Producing batteries is an extremely sensitive process. Each phase of the production environment, whether processing, transport or quality inspection, should therefore be clean.

Find out how to produce safe batteries with non-ferrous metal-free automation components in our catalogue 'Products for battery production'.

Automation solutions for your applications

Precisely controlled degassing and sealing

During the formation process, gas builds up in the battery cell. This gas must be removed. This is done by piercing the battery cell using a hollow lance and evacuating the gas until electrolyte is being drawn off too. The system then switches over and pumps the drawn off electrolyte back into the battery cell, and the rest of the gas is removed. Handling systems from Festo help with loading the battery cells onto the workpiece carriers for insertion into the process camera and then unloading them again afterwards.

Suitable products for degassing and sealing the battery cell

Augmented reality animation (only available in English)

Safe cutting and clamping with WebCatcher

The purpose of cutting is to divide a wide strip of electrode foil into several narrower strips. This cutting process can be done thermally using laser cutting or carried out mechanically using a rolling cutter. To extend the cutter’s service life, a cooling liquid is sprayed directly onto the blade during this process. The liquid must be dispensed in a controlled way and in very small quantities. The dispense head from Festo is perfect for this task. If the machine stops during the cutting process, the electrode strips are secured using what are known as WebCatchers. Fast-switching valves and cylinders are used to ensure a fast response time and speed.

Suitable products for cutting and clamping electrode strips

High-speed stacking

In the production of pouch cells a stacking process is used. During the stacking process, the electrode sheets are stacked in a repeating cycle of anode, separator, cathode, separator, etc. Festo offers complete electric handling systems for this particular process step, consisting of axis kinematics, motors and servo drives. All the components are perfectly matched. Very high speeds are required for maximum output. These are achieved by fast-switching valves with switching frequencies of up to 500 Hz. The vacuum needed to pick up and transfer the electrode sheets is generated using vacuum generators.

Suitable products for stacking electrode sheets

Safe and precise filling with electrolyte

Once the cell stack or jelly roll has been inserted in the battery housing, the battery cell can be filled with electrolyte. The electrolyte is dispensed via the pinch valve. It is actuated using individual valves or valve terminals. Since electrolyte reacts with water and forms hydrofluoric acid, the ambient air must be very dry when filling the battery cells. To ensure this is the case, the air is continuously evacuated and removed from the machine cell. The vacuum required to do this is generated centrally via a vacuum pump. The process is regulated by a system of pinch valves, valve terminals and pressure sensors.

Suitable products for filling with electrolyte

Success story: future battery production

Electric vehicles are setting a trend. However, their success depends on high-performance and cost-effective batteries. In the UK, the pilot project AMPLiFII at WMG is laying the foundations of a new generation of traction batteries. The project includes innovative automation technology from Horizon Instruments with a Festo pick & place solution.

FAQs about products for battery cell manufacturing

What are the requirements for products used in manufacturing battery cells?

Manufacturing battery cells is a highly sensitive process with a wide range of requirements. Contaminants such as copper, zinc or electrically conductive or non-conductive particles can reduce the quality of the batteries or render them unusable.

Since there is no set legal standard, Festo assesses its product design according to established criteria and on the basis of detailed customer specifications. To ensure the safety of battery cell production, cleanroom products and products with restrictions in terms of non-ferrous metals such as copper and zinc are often needed.

The production environment also plays an important role in the manufacture of lithium-ion batteries. Products in cell production are often exposed to a dry-room environment with condensation points as low as –80°C.

How does Festo define the restrictions concerning non-ferrous metals (copper, zinc, nickel)?

Depending on the electrolyte and electrode material, copper, zinc and nickel may cause problems in the production of lithium-ion batteries. It is for this reason that Festo has defined criteria restricting the use of copper, zinc and nickel in its product development: metallic materials with copper, zinc or nickel as a main component are excluded from use. However, some alloys require the addition of these elements within the metal matrix.

Exceptions to material restrictions concerning copper, zinc and nickel:

- Nickel in ferrous metals

- Electroless nickel plating without a copper sub-layer

- Inert chemical compounds, such as oxides and sulphides

- Printed circuit boards, electric plugs, cables, wires and coils

Which products meet the restrictions defined by Festo for copper, zinc and nickel?

Many standard products from Festo already meet the restrictions defined by Festo for copper, zinc and nickel. These are marked in the "Automation solutions for battery production" brochure and in the overview in our Online Shop.

Products for battery cell manufacturing

There are special variants of products that are often needed for cell production but do not meet Festo-defined restrictions as standard products.

These special variants are marked with F1A in the ID code and can also be found in the brochure and product overview.

Which Festo products are suitable for dry-room environments?

A dry-room environment with a pressure condensation point of –50°C down to sometimes –80°C is typical for lithium-ion cell production. The dry-room environment inhibits the hydrophilic tendency of many electrolytes and prevents the risk of harmful hydrofluoric acid forming through reaction with humidity in the ambient air.

Standard products from Festo have proven their worth in dry-room applications such as battery manufacturing. Festo products can be used in environments with a condensation point of –80°C or even lower, since none of the approx. 60 different lubricants from Festo contains water as a component of the formulation.

As a result, none of these lubricants dries out when they come into contact with even very dry air. Moreover, no Festo lubricant requires moisture or liquid water to achieve or preserve its lubricating properties.

Which solutions does Festo provide for cleanrooms?

You can use Festo cylinders, valves, grippers and drives, all handling, vacuum and compressed air systems, sensors, filters, regulators and fittings from more than 80 product ranges in ISO class 7 cleanroom environments. Most are suitable for use in classes 6 and 5, and many can even be used in class 4 environments. We can also provide customised special solutions.

All our cleanroom products are classified into cleanroom classes according to ISO 14664. It’s best to check the exact requirements with our specialists, because particle emissions depend on the application in question. That’s the fastest way to find a workable solution.

Expertise to download

For electric vehicles, battery production is the critical factor. Be part of the move to unlock the full potential – with automation technology from Festo.

Brochures to download

The race for efficient systems is already well under way. Our observations indicate that efficient automation can considerably reduce the costs of manufacturing batteries.

Why not share with your colleagues what Festo can contribute in this area?