Controlled Pneumatics digitalises pneumatics

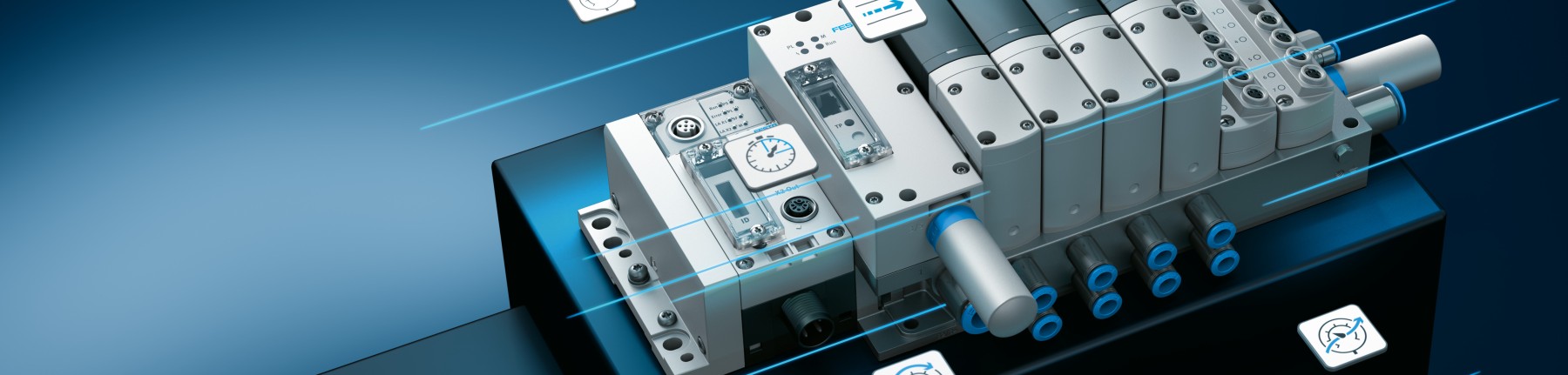

Innovative proportional technology, powerful sensor technology and intelligent control algorithms form a closed loop. This makes pneumatic applications significantly more precise, energy-efficient and reliable than ever before.

Sensors continuously record the actual value, the closed-loop controller compares it with the target value and automatically adjusts the valve. This keeps pressure and flow stable, even with load changes, strong disturbance variables or fluctuating input pressure.

This dynamic, precise and energy-efficient regulation significantly expands the opportunities of pneumatics. The result: greater precision, higher process reliability and noticeable energy savings.

Controlled Pneumatics – the right solution for your application.

"If you want to control processes precisely, stably and energy-efficiently, you need Controlled Pneumatics. By combining proportional valves, sensors and intelligent algorithms, the pressure, flow rate and movement can be controlled with great precision and dynamic response. Thanks to a wide range of communication interfaces, you can integrate Controlled Pneumatics into your machines and systems easily and seamlessly. The result is noticeably better performance, greater flexibility and improved energy efficiency."

Marco Schilling

Head of Product Management Controlled Pneumatics

Festo SE & Co. KG

Controlled Pneumatics FAQs

What is a pressure regulator?

A pressure regulator is used to keep the pressure in a pneumatic system constant, regardless of fluctuations in the input pressure or changing loads. In Controlled Pneumatics, the pressure is controlled digitally and extremely accurately, so that only the required compressed air is used. This saves energy, reduces wear and ensures optimum process control.

What is a flow control valve?

A flow control valve controls the amount of compressed air flowing through, which directly influences the speed of pneumatic actuators such as cylinders or grippers. With Controlled Pneumatics, this closed-loop control is automated and infinitely variable, enabling smooth motion sequences and precise adaptation to the process requirements. This not only optimises performance, but also reduces compressed air consumption.

What does closed-loop control mean in pneumatics?

Closed-loop control is a technological method in which sensors continuously measure the actual value of the pressure or flow rate and compare it with the setpoint value. Deviations are automatically corrected, so that Controlled Pneumatics can guarantee consistent process quality and maximum repeat accuracy. This reduces manual readjustments and makes processes more efficient and less prone to errors.

What is a proportional valve?

A proportional valve is a valve that not only allows for binary (open/closed) adjustment of the pressure or flow rate, but for continuous and real-time adjustment as well. This is done via an electrical signal that precisely regulates the opening of the valve. In Controlled Pneumatics, proportional pneumatic valves enable high-precision closed-loop control that allows for flexible, energy-efficient and adaptive process management.

How does a piezo valve work?

A piezo valve uses piezoelectric materials to regulate the pressure or flow rate with minimal energy input. It only needs power to switch over, but then remains in position and consumes no additional energy. This makes it really efficient and wear-free. Controlled Pneumatics uses piezo valves for maximum precision, fast reaction times and durable solutions.

What is the Festo Motion Terminal VTEM?

The Festo Motion Terminal VTEM is the first standardised platform that can control various functions using software apps, from pressure and flow control to complex motion control. This enables flexible adaptation to different applications, quick changeovers and savings of up to 70% on compressed air and energy.

How does Controlled Pneumatics reduce energy consumption?

Controlled Pneumatics uses sensors, digital control loops and proportional pneumatic valves to adjust the pressure and flow rate precisely to the current demand. This means that only the amount of compressed air that is actually required is used, resulting in up to 60% less compressed air consumption. Component wear is also reduced, which lowers maintenance costs and increases the service life of the system.

What does adaptive pressure and flow control mean?

Adaptive closed-loop control means that the pressure and flow rate adapt to changing process requirements dynamically and in real time. In Controlled Pneumatics, sensor values are continuously recorded and processed using intelligent algorithms to provide the optimum air flow for each application. This improves process stability and reduces unnecessary compressed air consumption.

What role do sensors play in Controlled Pneumatics?

Sensors are at the heart of Controlled Pneumatics, as they detect pressure, flow rate and load changes in real time. The data from the sensors is directly incorporated into the closed-control loop in order to automatically optimise processes. This ensures consistently high quality, reduced downtime and greater energy efficiency.

Why is Controlled Pneumatics future-proof?

Controlled Pneumatics combines digital closed-loop control, intelligent sensors and proportional technology to make automation systems more efficient, flexible and sustainable. The technology can be fully integrated into Industry 4.0 concepts, significantly reduces compressed air consumption and enables precise closed-loop control for modern production environments. This makes it the future-proof alternative to classic pneumatics.