Nereda technology is the new modern standard for sustainable and cost-effective biological treatment of urban and industrial wastewater. Unique to the Nereda process is that the bacteria used to purify the wastewater

grow in fast-settlinggranules. All biological treatment processes take place simultaneously in these granules.

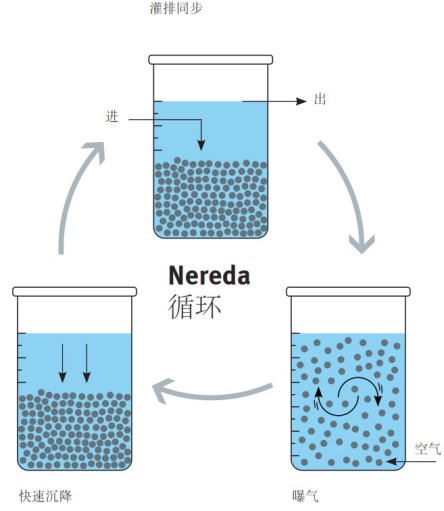

The Nereda technology is basedon a simple 3 step cyclic operation and takes place in one or

moreNeredareactors.Theduration and the process parametersfor thevarious stages of each cycle are automatically adjusted to guarantee optimum and efficient performance,even when the wastewater quantities, composition and temperature fluctuate.

- Infeed of the untreatedwastewater and simulta-neous decanting (displacement) of the purifiedwastewater.

- In the aeration phase, the simultaneous biological removal of organic, nitrogen and phosphorous compounds takes place.

- Fast settling phase during which the biomass isseparated from the wastewater and the Nereda plant is readyfor a newcycle.

Festo is a preferred supplier within the Nereda community

Festo provides support with thedesign of the overall pneumaticsystem as well as with installation and commissioning.For an optimised compressed air supply, Festo supplies turnkeysolutions with control cabinets,compressors, tubing and accessories.Compressed air monitoring ensures efficient and stable processes – and a warranty for the overall system with maintenance agreement is also available.

Maximum energy efficiency to DIN EN ISO 11011

The compressed air system isperfectly sized for maximumenergy efficiency and assessed by Festo to DIN EN ISO 11011. This is how you get reliable data for your energy and environmental management and further boost the optimisation potential of your plant.

Expertise and technology from a single source

Control cabinet solutions

For protecting the decentralised automation components from external influences.

MS series

Modular compressed air preparation with numerous configuration options such as pressure regulation and tamperprotection.

CPX/VTSA

Valve terminal VTSA for high flow rates for controlling large-volume actuators combined with the electrical terminal CPX for maximum function integration, such as pressure monitoring as well as digital/analogue inputs and outputs.

Features:

- Condensate drain to maintain the pressure dew point

- Compressed air monitoring

- Valve terminal VTSA with Modbus communication

- Pressure regulation and supply for field measuring equipment

- LED lighting, heating, and humidity control

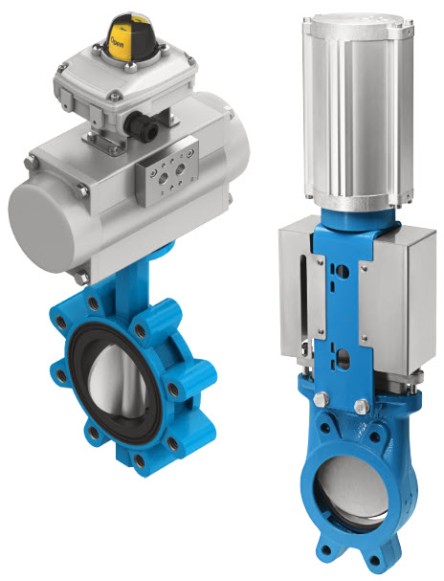

Process valve units

Pre-assembled process valveunits ensure that the components optimally match one another, make installation easier and give you planning certainty, even in the case ofcustomer-specific solutions.

Compressed air network

A perfectly sized compressed air network is crucial for energy-efficient plants. At Festo, you get everything from a single source, from the compressor and air preparation (e.g.dryer) right up to anextensive selection of

tubing and connectors –combined of course with advice from our experts.