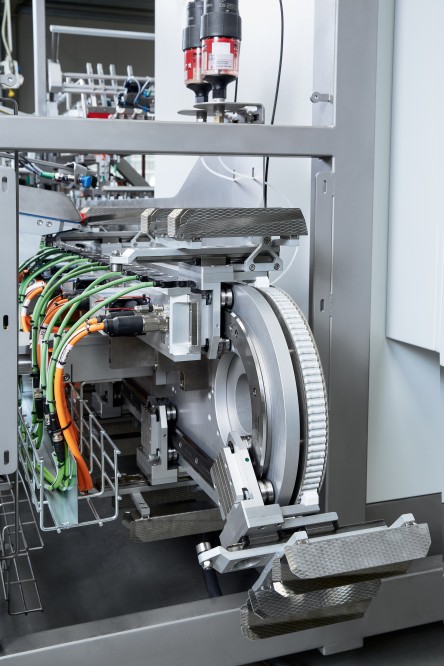

包装机的操作员有特定的系统要求:它们必须坚固、可靠且紧凑,允许高吞吐量并易于控制。包装机制造商 ECONO-PAK 已开发出一种具有出色精度和功能的机器。HK-S 非常紧凑,可确保包装过程可靠。用机器仅需一分钟,即可将 120 根表面对刮擦极其敏感的管子小心地装入纸板箱中。“Festo 的多滑块运输系统(简称 MCS)是系统的关键组件,”ECONO-PAK 的销售经理 Markus Zerbe 解释道。

短暂停止以供重新装载

在包装过程中,装箱机和 MCS 必须像乐团中的音乐家一样和谐地工作,因为机器的效率取决于它。在工位 1 上,进料器是一台输送机,以 0.41 米/秒的速度在两条线上精确、平行地将管子向工件架输送。在装载过程中,滑块会停下来,因而运输过程不会造成任何损坏。然后,滑块会加速以弥补损失的时间,并与并行运行的装箱机及推杆组件的速度(0.31 米/秒)保持同步。这些管子通过闸门连杆转移到纸板箱生产线上,并在连续过程中包装。滑块沿传送带完全无晃动地移动,并且振动极小。

同步至关重要

在工位 2 处,即插入区,产品推杆将管子推过产品托盘进入纸板箱。重要的是,沿着该部分,滑块必须与推杆组件完全同步,以避免管子与箱子之间发生碰撞。产品推杆离开产品托盘顶部后,滑块便可以恢复其自身速度。

诸多优点

滑块的垂直返回节省了空间,并且允许采用纤薄、紧凑的系统设计。此外,滑块返回时经过伺服控制的齿形带,这意味着滑块驱动器在此部分与线性电机技术无关。这降低了运营成本,并使系统的调整和控制更加轻松有效。

“但是,MCS 的主要优点是,它可以使产品滑块和纸板箱之间完全同步,从而精确地保持各个位置,”Markus Zerbe 说道。精确地保持填装位置对于确保管子轻轻滑入滑块且在传输过程中不被损坏很重要。“管子的完整性是重中之重,”Zerbe 说道。通过 MCS 的线性电机技术可以做到这一点。各个滑块可以相互独立地加速、减速和自由定位。MCS 因此在一条线上结合了循环和连续运动。对于系统操作员,MCS 的另一个好处是其封闭的再循环系统,该系统可以快速适应不同的条件。例如,可以随时将其他滑块集成到系统中,以应对生产高峰。据 Zerbe 表示,很容易将产能提高到每分钟 200 根管子左右。

ECONO-PAK GmbH

Im Baumfeld 21–23

55237 Flonheim

Germany

业务领域:包装解决方案的制造商和开发商,提供咨询、项目规划、设计和制造、组装和调试、生产监督及培训、售后服务以及特定格式的工具制造