对于有兴趣在电子设备制造领域使用自动化流程代替人工工序的人士,Festo 的最新技术为其解锁了巨大潜力。机器制造商也将从我们丰富的自动化专业知识中受益。

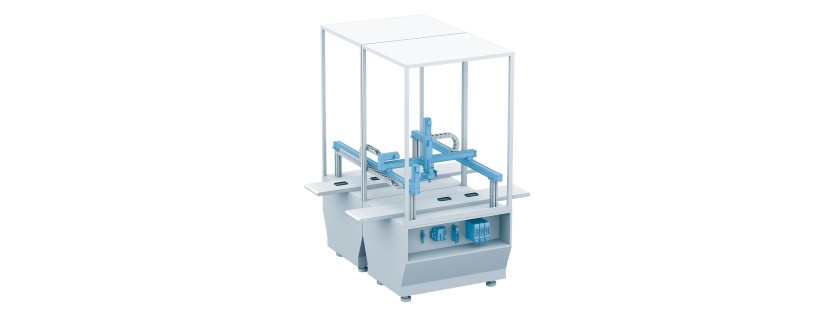

抓放:降低成本,节省空间

在抓放应用中,智能手机外壳能够可靠地从传送带上取下或放回原处。

我们提供了一种经济高效且节省空间的抓取系统,非常适合此类应用,该系统由以下经久验证的机械组件组成:直线电缸 ELGC、小型滑台式电缸 EGSC 和旋转电缸 ERMO。

该运动系统也可在后期阶段用于制造过程中几乎所有必要抓取操作。选择电机和驱动器时,请利用所有选项,从具有基本功能的解决方案到高性能版本。

我们还专门为亚洲制造商开发了伺服电机 EMMB-AS 和电机控制器 CMMB-AS,包括基于脉冲序列技术的接口选项以及防护等级高达 IP20 的连接器。

前端单元包括作为 Z 轴的小型滑台式电缸 EGSC、旋转电缸 ERMO、紧凑轻巧的真空发生器 OVEL、真空吸盘 ESG 以及用于工件检测的视觉传感器 SBSI。

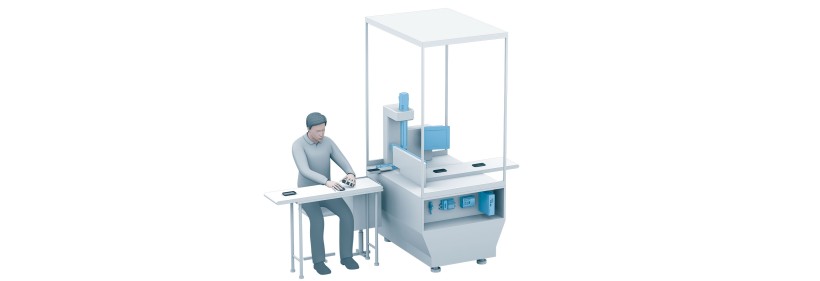

拧螺丝:精准放置并紧固

要将印刷电路板组装到智能手机外壳中,必须先将其从工件托架中取下。

为此,使用直线电缸 ELGA 抬起并移动工件托架。然后将印刷电路板 (PCB) 精准地放置在外壳中,并用自动螺丝刀固定,同时由我们的图像处理系统进行监控。无需费时的人工操作,而是通过导向杆气缸 DFM 对准并固定外壳。压力传感器 SPAN 指示夹紧气缸的压力水平。

气动系统由新型模块化控制器 CPX-E 和 Festo 核心产品法内中价格实惠的阀岛 VTUG 共同控制。结合我们的模块化自动化理念,在这种情况下,该电动抓取单元还包括直线电缸 ELGC 和小型滑台式电缸 EGSC。该系统非常特别,因为所有电缸都直接连接,并未使用转接板。

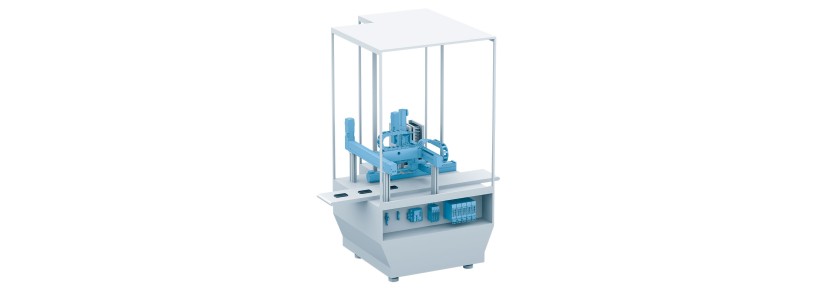

点胶:速度更快,精准到位

为了自动、快速、精准地将胶粘剂滴到智能手机外壳上,我们提供的解决方案为超紧凑型平面门架 EXCM-40,并配有步进电机 EMMS-ST 和控制器 CPX-E。如有更高的性能要求,可以选择带有伺服电机 EMMS-AS 和电机控制器 CMMT-AS 的平面门架 EXCM-40。

在两种情况下,导向杆气缸 DFM 都会对齐输入的工件,然后将其夹紧。压力传感器 SPAN 指示夹紧气缸的压力水平。最后,比例压力阀 VEAB 可以精确控制点胶剂量。自动化的其它优点包括没有过量凸起的胶粘剂、无需返工且胶的消耗量更少。

压装:均匀且受控

小心地将显示屏手动放置在智能手机外壳中,随后全自动压装站将接管进一步的处理。

在该步骤中,使用指定的受控力将两个部分压合在一起。

该作业非常适合伺服压机 YJKP。它由模块化操作软件和 Festo 的配套标准组件组成:丝杆式电缸、电机、电机控制器、力传感器和控制器 — 电驱压装应用(最高输出可达 17 kN)所需的一切应有尽有。

在应用中,工件通过一个气动系统进行移动,该系统由无杆气缸 DLGF、紧凑型导向杆气缸 ADNGF、真空发生器 OVEL 和真空吸盘 ESG 组成。

伺服压机 YJKP 的价格比传统压机系统便宜得多,在生产率方面为您提供了显著的竞争优势。

从始至终高速堆放和包装

在生产过程的这一阶段,将智能手机从装配线上移至工件托架中,然后堆放在存放库中,以便送入后续处理步骤。

带有平面门架 EXCH 和小型滑台式电缸 EGSC 的高速抓放系统在这一过程中起着主导作用。

我们用于检测和对齐智能手机的图像处理系统可确保以所需的精度完成此操作。然后,使用悬臂式系统将智能手机放在存放库中,该悬臂系统由标准直线电缸 EGC 和 ELGC 以及旋转电缸 ERMO 和抓手 HGPT 组成。也可以使用标准直线电缸 EGC 上下移动存放库。

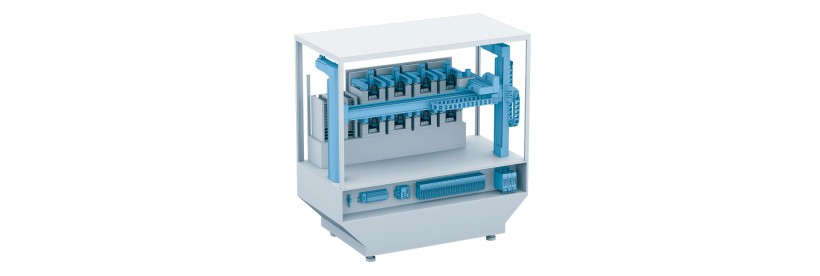

测试:安全、可靠且完全自动化

智能手机到达测试站,堆放在存放库中。通过高速抓放解决方案 EXCH 结合 ELGC、EGSC、ERMO 和 HGPT 组成的紧凑实惠型抓取系统,将它们可靠地从存放库运输到测试设备。

在测试设备中,各工件托架由几个紧凑型气缸 DPDM 固定。我们的紧凑型抓取系统 EXCM 和新型超短小型滑台式气缸 DGST 支持触摸屏的测试,而小型滑台式电缸 EGSC 将用于电气功能测试的插头精准地连接到智能手机。

贴标:精准可靠

在智能手机的组装中,最终的生产步骤之一是在显示屏上贴保护膜。自动化可确保此过程安全可靠。

移动带有保护膜(标签)的滚筒,并通过标准气缸 DSBC 固定在系统中。通过真空吸取保护膜,然后将其精准地贴到智能手机上。与先前的工作站相同,真空发生器 OVEL 产生真空,抓放系统进行贴膜操作,该抓放系统上安装有直线电缸 ELGC 和旋转电缸 ERMO。