How can you benefit from the Motion Terminal VTEM?

Reduce complexity through digitalisation

- Simpler engineering, commissioning and operation: the Motion Apps with their numerous functions replace up to 50 individual functional components, thus simplifying the design. There are far fewer part numbers and the system takes up less space.

- The integrated, intelligent sensors for control, diagnostics and self-learning tasks eliminate the need to integrate additional components in the system.

- Copy and paste: once the parameters have been defined, you can simply copy them over to other systems. The process of time-consuming manual settings and adjustment is a thing of the past – all drives are optimally synchronised.

- Accidental manipulation is ruled out.

Use the ease of adaptation to increase your productivity

- Significantly minimise your set-up time: set the parameters once and then use them over and over again. With presets there is no need to spend time setting new parameters manually during format change-overs.

- You can achieve maximum process stability as the Motion Apps always provide exactly the same parameters. They can regulate themselves if there are deviations and adapt independently to changes in conditions.

- Reduce cycle times by up to 70%, for instance with the ’Soft Stop’ Motion App. The smooth movement to the end position prevents wear-intensive vibrations almost completely, for example for tool changeover doors.

- Save up to 40% on energy while still making the cylinders up to 30% more dynamic thanks to the clever use of compressed air, for instance by selecting the right parameter set for each product and defining a lower pressure for the return stroke.

- Overall, you can achieve optimum modelling of motions with a highly customised combination of pressure and flow rate and also vary the speed of travel within a working stroke – for example when switching from speed to maximum force in a pressing operation.

Call up your process data at any time

- Improve the overall equipment effectiveness (OEE) by making decisions based on historical or current data.

- Integrate predictive maintenance into your diagnostics concept and analyse the process data made available by the sensors you integrated. This helps you to tailor your maintenance to the actual requirements and plan your maintenance cycles more effectively.

- Use the "Leakage diagnostics" Motion App to check your application regularly and identify potential leaks at an early stage. This saves you energy and costs.

- Increase reliability with traceability. Digital monitoring of all key process parameters enables convenient traceability for the first time – without the need for additional components.

- Optimise your system with the test functions. WebConfig allows you to check each motion in advance via the web server, independently of a higher-lever controller, and identify the performance limits of your system.

- Interface standards for Industry 4.0 thanks to OPC UA, using the CPX automation platform.

More communication is key to your future success

The advanced decentralised communication of the Motion Terminal expands the possibilities of pneumatics. It also becomes much easier to implement functions that would previously have required complex designs and time-consuming settings. The movements can be created with significant differences and also with new sequences. In addition, key parameters such as the travel time, pressure and flow rate can be checked via this communication and automatically corrected if necessary. The intelligence of the Motion Apps provides numerous options, for example for controlling and analysing related processes – including in networks.

App-based functions, integrated intelligence

The Motion Terminal functions are implemented using Motion Apps and integrated, flexible and programmable processors. This integrated intelligence makes the system much more flexible than wired hardware. You can now make adjustments decentrally within the system. You need significantly less bandwidth for the communication, while controlling and programming the entire system also become much less complex.

Disconnected: functions and hardware

The Motion Terminal is equipped with powerful processors. Thanks to this decentralised intelligence in the integrated controller [1] and the Motion Apps [2], the pneumatic functions are, for the first time, uncoupled from the mechanical hardware. You can easily assign these functions via apps. Plus, you now require just a single valve type for an extremely wide range of pneumatic movements.

Integrated sensors for new flexibility

Integrated sensors provide the valves in the Motion Terminal with intelligence. This new flexibility enables components such as cylinders to perform new tasks. Movements can be very individually modelled and adapted extremely efficiently to the relevant task. This brings significant performance gains for your production and generally reduces your costs, including if you are retrofitting systems.

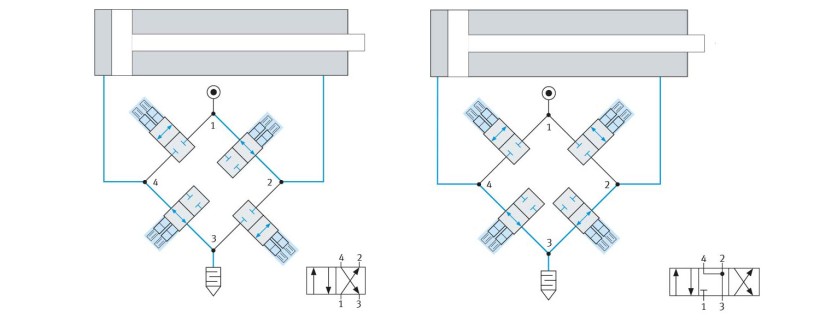

A bridge circuit with integrated sensors that is made up of four proportionally controlled 2/2-way valves creates the smart actuator technology in the Motion Terminal. Piezo pilot and diaphragm poppet valves carry out the core tasks of independent pressurisation and exhaust. This means that you can realise a wide range of common valve functions in one valve, even proportional pressure regulation or complex control solutions such as Soft Stop.

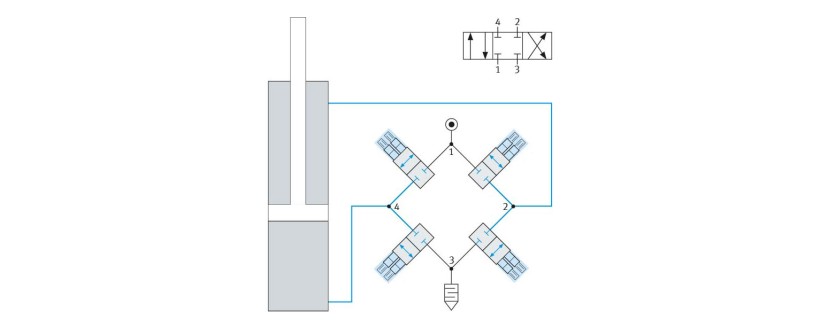

Setpoint-actual comparison for self-adjusting parameters

Built-in sensors are indispensable in an intelligent, flexible system that is capable of learning. They can be used for adapting to changes in ambient conditions or system parameters such as fluctuations in supply pressure, or for reading out all the relevant information for big data processes.

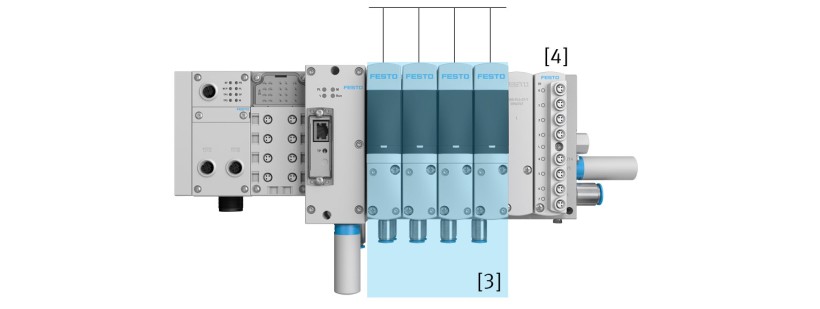

The combination of integrated sensors [3] and the software-based, flexible adjustment of pressure and flow rate enable the system to carry out its own evaluations and adjustments. This not only saves you money, but also simplifies the entire system, from conceptualisation to modernisation. You therefore no longer need, for example, external load cells for condition monitoring during pressing procedures. Or you can reduce the cycle time by varying the process parameters, even within a stroke. You can then often also use smaller cylinders.

For certain tasks, data can be obtained in real time from external sensors via separately integrated inputs [4] that enable internal control. You can use this to develop optimised applications with pneumatics.

You can also use it to cost-effectively integrate intelligence and transparency into your tried-and-tested existing systems during modernisation – making retrofitting really worthwhile.

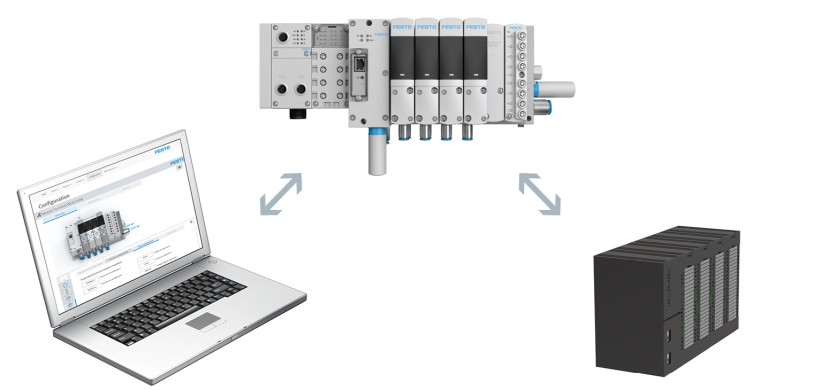

Simple configuration via the user interfaces

The Motion Terminal makes several communication channels with user interfaces available for you at the same time. Adjustment is quick and easy: directly via the Ethernet connection, your web browser, the intuitive WebConfig interface or the process data of a conventional machine control system. The simple function configuration offered by our Motion Apps will help you to speed up commissioning, reconfiguration and system adaptations. You can read out data via a transfer channel.

Fit for the future with communication interfaces

Open, global communication interfaces make the Festo Motion Terminal ready for future developments, such as software services and global networking. You can also use the OPC UA interface on the CPX-CEC to create a service-oriented architecture that is both platform and manufacturer-neutral – the ideal prerequisites for Industry 4.0.

At the same time, the CPX bus nodes [5] and the multitude of available I/O modules provide a tried-and-tested standard for communication in machine and production networks.