选择合适的测量设备

首先,液体搬运结果取决于测量结果的可靠性。若测量不当,造成实际搬运量和测量量之间存在很大误差,那么会得出错误的结果数据。因此,选择合适的测量设备至关重要。ISO 8655 和 ISO 23783 对各种测量方法及测量条件做出了描述,包括不同体积范围内允许的最大系统及随机测量偏差。然而,需要满足这样的基本要求,周围环境条件要尽可能保持恒定,以便排除外部和内部影响。

排除外部影响

即使测量设备没有问题,实际结果也可能不尽人意,而这些结果并非由分液头或移液头引起。典型的错误及其应对措施如下:

- 系统内含有空气

- 原因可能是:液体未脱气,组件太多,管径膨胀导致管道裂开等等

- 应对措施有:清洗系统,从头至尾采取错误避免管径增大,减少组件数量

- 系统内有颗粒物,阀未密封

- 原因可能是:产品受污染,过滤不充分,配件选用错误,附件受损,等等

- 应对措施有:安装前对产品进行清洗,冲洗系统时增大压力,选用液体专用配件(如 NLFA),选用合适的气体及液体过滤器

- 重复性差

- 原因可能是:阀调节较慢,通道间压力下降,罐内容积减少导致压力下降,组件存在公差,等等

- 应对措施有:使用快速控制模块(如 Festo VAEM-V),对每个通道/阀门进行校准,在容器后侧使用液体压力传感器

- 其他环境条件

- 原因可能是:温度不恒定,存在振动,管道较长,等等

- 应对措施有:尽可能保持环境条件稳定,尽量减少外部影响,尽量减少管道长度

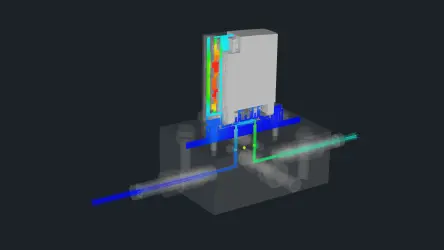

消除内部影响

如前所述,外部因素会极大影响搬运结果。尽管如此,即使对特定的分液头和移液头进行微小改动也能改善结果,当移液目标体积较小时尤其如此。Festo 采用压控式分液和移液方法。这种方式必须要使用重复性和再现性良好、且不受停顿时间影响的阀门。在实际分液的过程中,选用合适的滴定头也是非常重要的。

我们可以用 Festo 的滴定头 VTOE 来对此进行验证。通过观察使用不同直径滴定头的分液结果,我们可以得出这两条结论:

- 高线性度:容量一定时会产生线性过程,这一过程与开放时间和滴定头直径有关。

- 在针头直径不同的情况下,要想达到相同的分液量,就需要不同的脉冲时间。

测量条件

- 供压 300 mbar

- 室温 23 °C

- 水性溶液(水)

- 电压 24 V,无保持电流降低

与滴定头分液结果相对应的通道偏差系数(也称为运行中或检测中偏差系数)也是一个值得注意的量,由这个量,我们还可以发现到两条重要的信息:

- 这些偏差系数都很小,意味着该系统能够带来出色的结果。

- 随着脉冲时间的减小,偏差系数会增大。

测量条件

- 供压 300 mbar

- 滴定头内径 0.60 mm

- 室温 23 °C

- 水性溶液(水)

- 电压 24 V,无保持电流降低

偏差系数随脉冲时间的减小而增大,其原因很简单:当阀打开和关闭时,有许多参数和属性(如时间控制单元分辨率、阀的开关特性、液体流量等)都会有轻微的变化。若脉冲时间较短,则开关阀的时间占比较高,因此影响较大。其结果是,分液结果更为分散,偏差系数更差。

为避免这种情况,就需要用到从第一张图得出的结论。使用流速较低(如内径较小)的滴定头,可以增加脉冲时间,从而达到一定量的体积。这样一来,当目标体积相同时,偏差系数又会变得更好。

总结

综上所述可明显得出这样的结论:液体搬运结果的好坏取决于若干参数。首先,必须要有合适的测量设备。此外,一定要避免外部影响。我们要设计合适的流体通道,创造清洁的工作环境,尽可能保持环境条件的恒定。最后,我们要根据实际应用情况,选用正确的组件,此举可以消除内部影响。